Efficient powertrains, reliability on the road

Electric powertrain: Bosch manufactures economical and efficient electrification solutions for both light and heavy commercial vehicles. The Bosch e-axle is easy to integrate into commercial vehicles of up to 7.5 metric tons. One benefit of this is that fleet operators will still be able to serve delivery routes in restricted areas such as urban low-emission zones in the future. Bosch’s electric motor and inverter already feature in a heavy-duty, purely battery-electric commercial vehicle. Here, an 800-volt operating voltage and the silicon carbide chips used enable longer ranges and shorter charging cycles for efficient goods transport, even over long distances.

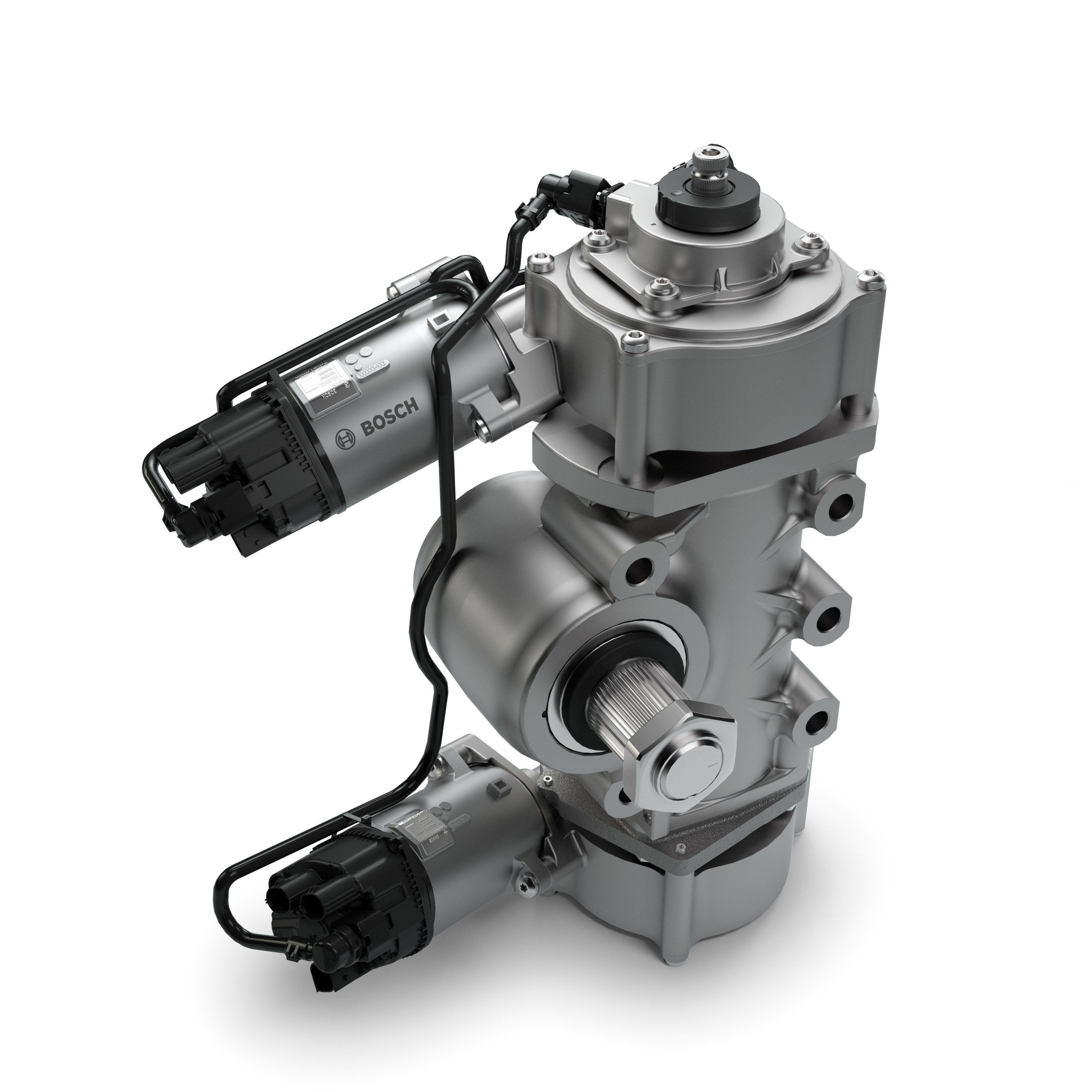

Fuel cell: Commercial vehicles can also be operated in a climate-neutral way with a fuel-cell system. This technology is particularly suitable for longer journeys and maximum payloads, making it a sensible addition to battery-electric trucks. Bosch already has a 200-kilowatt fuel-cell system in large-scale production. The company is now working on the Fuel Cell Power Module Compact 300, which will be even more compact and, with an increased output of 300 kilowatts, also more efficient. In addition to this type of complete solution, Bosch also offers individual system components and submodules as well as components for hydrogen storage systems, enabling it to provide every customer with the right solution

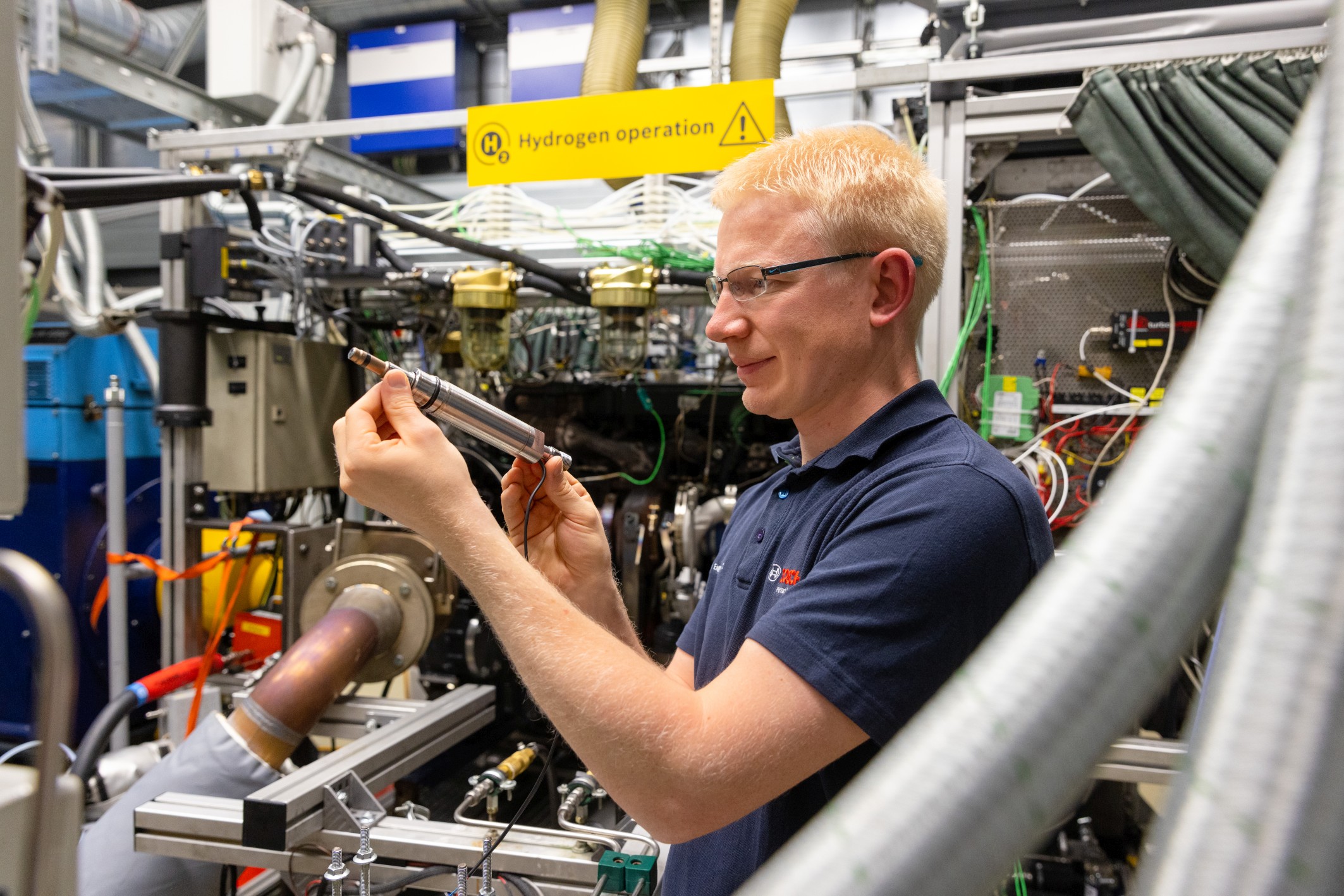

Hydrogen engine: Another option for the climate-friendly transportation of goods by road is the hydrogen engine, which will initially be used in heavy trucks. At the beginning of 2024, the EU also recognized this powertrain solution as climate neutral. Derived from established diesel and natural-gas engines, this concept lets engine manufacturers use more than 90 percent of existing development and production technologies. Bosch is developing the key components of the injection system for the hydrogen engine, including a new injector for direct injection that requires no additional lubrication and is scheduled for launch in 2026. The first hydrogen engines equipped with Bosch intake manifold injection are set for launch in 2025.

H2 tank system: The main challenges in the design of H2 tank systems lie in storing the hydrogen safely under high pressure and controlling the supply of the highly flammable gas. ITK Engineering GmbH supports and advises vehicle manufacturers throughout the entire development process, from the design to the implementation of a safe, certified H2 tank system. When designing systems, ITK Engineering also relies on digital twins for physical simulation so it can achieve maximum safety and efficiency.

Connectivity solutions: Fleet operators and vehicle manufacturers can also further improve the efficiency of their vehicles with Bosch digital services. The technical basis for this is the Automotive Connectivity Hub – a solution that can be retrofitted to any vehicle regardless of manufacturer, providing access to the vehicle’s operating and diagnostic data and thus enabling a wide range of data-based services. With the efficiency services, such as the Retrofit Efficiency module, the speed can be easily adjusted as needed in line with empirical values stored in a central database, thus reducing consumption by up to 4 percent. Vehicle Health, in turn, records both standardized and manufacturer-specific error codes as well as notifications in the vehicle and evaluates them in the cloud. Any impending problems are recognized at an early stage and presented in an understandable way, and immediate responses such as prioritized servicing are suggested. This significantly reduces the number of unexpected breakdowns, which makes it much easier for operators to plan. For electric vehicles, Battery in the Cloud for example offers an improvement in the performance and service life of high-voltage batteries. With the help of continuously recorded data on battery status and usage, it can analyze high-voltage batteries, predict their aging and defects, and optimize their rapid- charging behavior for greater durability, which improves the reliability and economy of electric vehicles. The Digital Fuel Twin is ideal for fleet operators who want to use alternative fuels such as HVO for their existing fleet. This function can verify the use of these fuels and thus the reduction in CO2 achieved – in a fully automated way that is certified for auditing. To monitor the condition of the vehicle or fleet in real time, RideCare Insight uses an intelligent sensor box to detect potential bodywork damage, in-vehicle smoking, and risky driving maneuvers in light commercial vehicles.

On course for the future with steering systems

Fully electric power steering: The ServoE steering system augments Bosch’s product portfolio to include a fully electric steering system for heavy trucks. This electromechanical steering system enables simple and oil-free assembly, while the power-on-demand function guarantees eco-friendly driving. Steering function and feel can be tailored to customer requirements.

Servotwin: The Servotwin electrohydraulic steering system for heavy commercial vehicles combines a hydraulic Servocom steering system with scalable electrical servo units and intelligent software architecture. This supports SAE Level 2 steering assistance and driver assistance functions as well as automated driving functions up to and including SAE Level 4.

Rear-axle steering system: The electrohydraulic steering system for rear axles is a stand-alone power-on-demand system. It enables the steering of three or more leading or trailing heavy-truck axles. Steering the additional axles, if required, reduces the turning radius and tire wear. Thanks to its compact design, this Bosch technology can be adapted to all powertrain types. The intelligent software architecture supports safe and eco-friendly driving and protects the steering system against external attacks.

Steering shaft: The modular and weight-optimized steering shaft is the connection between the steering mechanism and steering column and is used in medium- and heavy-duty commercial vehicles and buses. In vehicles fitted with a Bosch steering shaft, relative movements between the driver’s cab and chassis that occur during driving have no effect on the steering behavior. Its design features impressively compact construction and low friction.

EPSapa highload: The high-load version of the long-established electric power steering with parallel-axle servo unit (EPSapa) has no difficulty driving on asphalt, gravel, or rough terrain. This new variant not only expands the Bosch electric power steering portfolio, but also fills a niche: thanks to increased steering-rack force and exceptional robustness, this steering system is – unlike previous variants – ideally suited for heavy SUVs, vans, and off-road pickup trucks. This makes EPSapa highload ideal for the North American market.

Smart road safety: the vehicle as a mobility platform

E/E architectures: With customized consulting and engineering services, Bosch Engineering supports manufacturers in the transition from hardware- to software-defined vehicles. The focus here is on defining a new electrical and electronic architecture to reduce the complexity of the process and cut integration costs.

Cloud-based diagnostic solution: Automakers and their suppliers have a common task: providing authorized workshops with service solutions so that they can carry out repairs and maintenance to ensure vehicle availability and customer satisfaction. This is particularly important for new technologies such as fuel cells, for which practical experience can be gathered only gradually. ETAS has a solution that takes diagnostic and repair capability into account during development, meaning it is available before the start of production. It enables manufacturers to significantly reduce the time to market for diagnostic and repair concepts while ensuring that the solution is always up to date with a cloud?enabled platform. This concept can also be applied to all the other complex components in modern vehicles. The mobile version enables diagnostics directly on the vehicle, whether in the workshop or on the road.

Connected map services: With the help of swarm data from connected vehicles and infrastructure data, Bosch map services provide accurate and up-to-date information about the driving environment. Here, the function benefits from the sum of information from all connected vehicles, from which attributes such as optimum driving speeds, exact lane geometries, localization landmarks, and current road conditions can be derived. Based on this real-time information, driving behavior can be planned predictively and safely and adjusted if necessary. In this way, connected map services not only improve existing driver assistance functions and increase their availability, but also create new possibilities for developing and improving vehicles and mobility services, thereby making the mobility of the future safer and more convenient.

Software platform for logistics specialists: Bosch’s digital service platform for logistics (L.OS) addresses many of the challenges facing the transportation and logistics industry. At the heart of the software ecosystem for freight forwarders and carriers is a marketplace that offers centralized access to various providers’ digital solutions for all aspects of the logistics business. But the platform is much more than just a marketplace. It enables the seamless integration of previously separate services and data. For example, software providers such as Webfleet, Europe’s biggest fleet management system, are working with Bosch L.OS to offer fleet managers value-added services within their fleet management solution. This enables their users to activate new and value-creating functions without having to carry out their own costly and time-consuming IT projects. Bosch is working on this with Amazon Web Services. The first use case involved integrating Bosch Secure Truck Parking, the leading European booking platform for secure truck parking, into the Webfleet fleet management system via Bosch L.OS. This allows Webfleet customers to easily find and book truck parking spaces for their fleets without having to leave the application. It also helps companies to increase safety for drivers, vehicles, and goods and to better plan the estimated time of arrival. Cutting the time spent looking for a parking space also reduces fuel costs and CO2 emissions and helps ensure driving hours are not exceeded.

Secure connectivity and communication: A prerequisite for numerous smart services that make driving safer and more efficient is for vehicles to be able to exchange data with objects in their immediate vicinity and with the traffic infrastructure. The basis for this is the Bosch Connectivity Control Unit for commercial vehicles (CCU). It uses wireless interfaces to connect the driver’s vehicle with the cloud, the infrastructure, and other vehicles. The Central Gateway links the vehicle domains, serves as a router for in-vehicle communications, and communicates with the outside world via the CCU. It acts as a secure data distributor for communication within commercial-vehicle systems and is also the gateway for all data entering the vehicle. The Central Gateway supports various bus systems such as Ethernet and CAN.

Powernet Guardian: The Bosch Powernet Guardian is a holistic concept for the vehicle electrical system. It ensures that safety-relevant functions in commercial vehicles are supplied with power at all times. If a fault occurs, the Powernet Guardian takes over the function of an electronic circuit breaker, disconnecting the safety-relevant vehicle electrical system from the other consumers. This protects them from under- or overvoltage and, by extension, can prevent malfunctions or reduced functionality. By digitalizing the power supply, the Powernet Guardian enables intelligent power distribution functions that also make it possible to switch loads according to demand and vehicle electrical system capacity.

Convenient vehicle access: Fleet Management Xtended Access is a digital vehicle access system that allows the driver to access the vehicle via a digital key on a smartphone and – depending on the variant – also to start the engine. Manufacturers can integrate the system components directly into their commercial vehicles according to their needs. They have the option of retrofitting their vehicle fleet with the Fleet Management Xtended Access Kit. This flexible combination of ultra-wideband, Bluetooth Low Energy, and near-field communication technologies enables manufacturers to provide secure and user-friendly access to vehicles and permits the scalable introduction of a digital vehicle access system that can replace their existing systems.

Truck cockpit technologies: Bosch’s cockpit technology solutions include a platform for integrating instrumentation and infotainment applications and a digital mirror replacement system developed with Mekra Lang to replace conventional mirrors. The Driver Monitoring System for commercial vehicles detects driver fatigue and distraction at an early stage and warns the driver. In addition to these safety-related functions, the Bosch platform supports various convenience functions.

Infotainment in coaches: The Bosch Coach Infotainment series makes next-generation infotainment available for professional use in coaches. Perfectly coordinated components provide a new experience for drivers and in the passenger compartment. Enjoy movies, surf the internet, watch TV, listen to music, and hear announcements clearly – all this is possible with Bosch infotainment systems for coaches. Ethernet AVB technology provides optimum synchronization between image and audio signals, ensuring smooth playback of HD media content with very low latency.

Keeping an eye on the environment

Smart eyes: The third generation of the multifunction camera is tailored to the requirements of heavy trucks. With its unique multipath approach, the camera combines conventional image processing algorithms with AI-driven methods, giving it a key role in high-performance driver assistance systems. It reliably detects and processes objects and structures and uses an innovative, high-performance system on a chip for image processing. The camera is designed for safety-relevant driver assistance systems and convenience functions such as the lane-keeping support system, and it also supports object-based functions such as automatic emergency braking. Moreover, it permits implementation of other functions such as traffic sign recognition. This means the system supports the legal requirements of the EU General Safety Regulation on intelligent speed assistance for detecting speed limits and warning of exceeding them.

Precise object detection: The fifth-generation front and side radar ensures greater safety in the heavy truck segment, thanks to reliable and precise object detection in the area to the front and side of the vehicle. Thanks to the sensors’ large detection range and high angular resolution, as well as their wide aperture, they can detect complex driving situations very quickly, accurately, and safely. They employ novel chirp-sequence modulation to improve surround sensing by producing more detailed reflections. As a result, both the front and side radar solutions are extremely precise when detecting and distinguishing between objects and people as well as their position, relative speed, and direction of movement – even when visibility is poor. This means that Bosch radar sensors in heavy trucks can ensure greater safety for the driver and other road users by supporting functions such as automatic emergency braking and by helping to meet legal requirements.