LAS VEGAS - Bosch is committed to the advancement of hydrogen, providing solutions for multiple technologies along the entire hydrogen value chain. The provider of technology and services offers an expanding range of components for both mobile fuel cells and hydrogen engines to optimize engine performance. It also is developing cryopump technology to support faster re-fueling times and electrolyzer technology for the production of hydrogen. Bosch has reaffirmed its business expectations in the growth area of hydrogen: by 2030, its sales with hydrogen technology could reach nearly $5.5 billion globally. In 2023, Bosch invested around $530 million (500 million euros) globally in the development and manufacturing of its hydrogen technologies and plans to invest around the same amount in 2024.

At the 2024 Advanced Clean Transportation (ACT) Expo in Las Vegas May 20-23, Bosch will showcase key elements of its hydrogen portfolio in Booth #1444.

“Hydrogen is a key tool on the path to reducing emissions and developing alternate propulsion options,” said Paul Thomas, president of Mobility, Americas for Bosch. “We are applying our systems know-how and industrial excellence to help drive forward hydrogen solutions for our customers.”

Components and systems knowledge for hydrogen engines

Bosch is developing components and applying its system knowledge to support hydrogen engines and the company expects the market for hydrogen engine technology to be worth around $1 billion globally by 2030. In fact, a first hydrogen engine with Bosch components is set to debut this year.

From a technical point of view, Bosch believes hydrogen engines represent a rapid path for reducing emissions in commercial-vehicle transportation and are a viable option along with battery-electric drives and mobile fuel cells. A major reason is that existing powertrain technology from today already provides a solid platform for hydrogen engines. Approximately 90 percent of existing development and manufacturing technologies can be re-utilized, as the basic structure of the fuel, air and exhaust system can be adopted from existing powertrain solutions. Additionally, existing skill sets of workforce can be naturally applied. And last but not least, hydrogen engines use very few rare earth materials.

“Hydrogen engines can be a powertrain of choice also for applications that require sustained high loads and robustness in challenging environmental conditions,” Thomas said. “We see this kind of application relevant for heavy long-distance transport as well as for agricultural and construction machinery.”

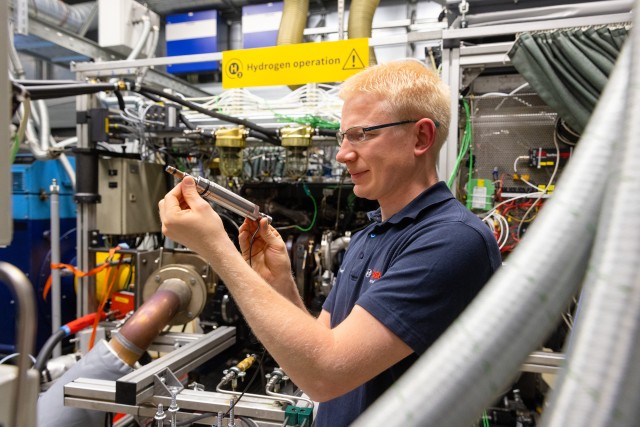

Next to port-fuel injection solutions, Bosch engineers are working to create specialized low-pressure direct injection systems for hydrogen engines that meet the performance and durability requirements of the commercial vehicle industry. In addition to fuel injection, Bosch as a system supplier for hydrogen engines also offers the electronic control unit, products for the storage and supply of hydrogen and further powertrain components as well as system engineering services.

The mobility industry is collaborating to show the opportunity in hydrogen engines. Bosch is among a group of industry collaborators supporting a Southwest Research Institute (SwRI) joint industry program that retrofitted a Class 8 heavy-duty vehicle with a hydrogen engine to demonstrate the low-CO2 and low-emissions potential’of hydrogen-powered engines using current technology. The vehicle will be on display at the 2024 ACT Expo.

A full portfolio to support mobile fuel cells

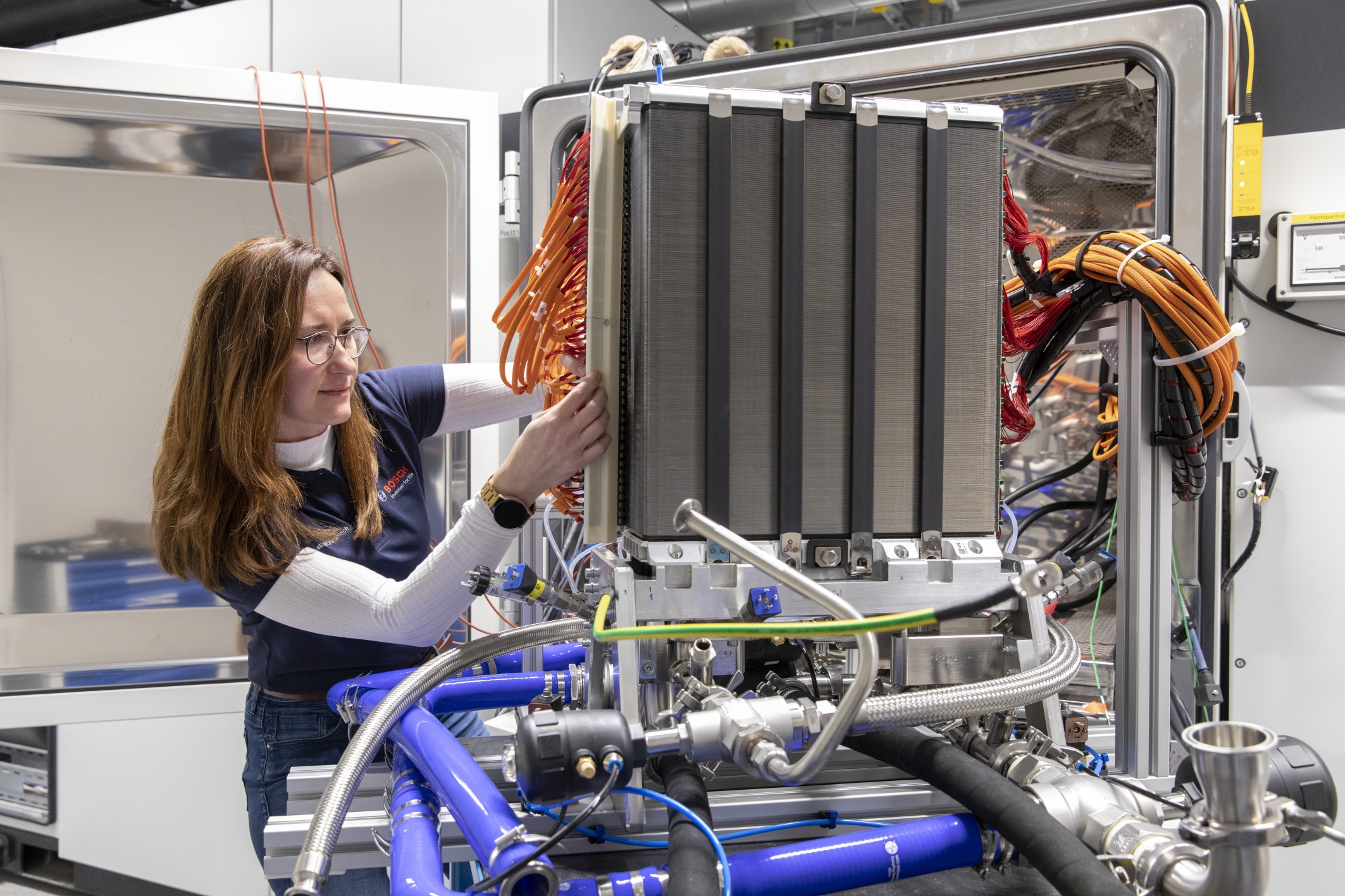

Bosch continues to provide customers with options in the area of mobile fuel cells. Already, the company is in production with the fuel cell power module to support global customers. Based on the learnings from the on-road experience, Bosch is exploring a next generation of the fuel cell power module with an increased power target of 300 kW and improved power to weight ratio.

The company offers a full portfolio of fuel cell components and sub-systems. Some of the key systems and components are the fuel cell stack, the electric air compressor, the anode recirculation blower, the anode module, the hydrogen injector, the fuel cell power transfer unit and the fuel cell control unit. These components perform critical functions that control the supply of hydrogen and oxygen to the fuel cell stack.

“The diverse experience at Bosch provides our customers with a variety of options to match their needs as they bring mobile fuel cell vehicles to market,” Thomas said.

Solutions for service, re-fueling and hydrogen production

Bosch is active on other aspects of the hydrogen value chain. As part of its Mobility Aftermarket business, Bosch brings together its comprehensive expertise in hardware, software, and repair solutions to prepare service centers for the latest vehicle technologies in the market. The company’s vehicle service readiness solutions include support for servicing vehicles equipped with electric and fuel cell powertrains.

In addition to the solutions shown at the ACT Expo, Bosch is also active in hydrogen re-fueling solutions and hydrogen production. Based on its decades of experience in hydraulics, Bosch Rexroth is developing customized solutions for an economical hydrogen infrastructure, working together with collaborators. The aim is to refuel Heavy Goods Vehicles (HGV) with 100 kg of hydrogen in less than 10 minutes. Working with the market leader for the commercial operation of hydrogen filling stations in the USA, FirstElement Fuel in California, Bosch Rexroth has developed a cryopump that can compress up to 600 kg of liquid hydrogen per hour.

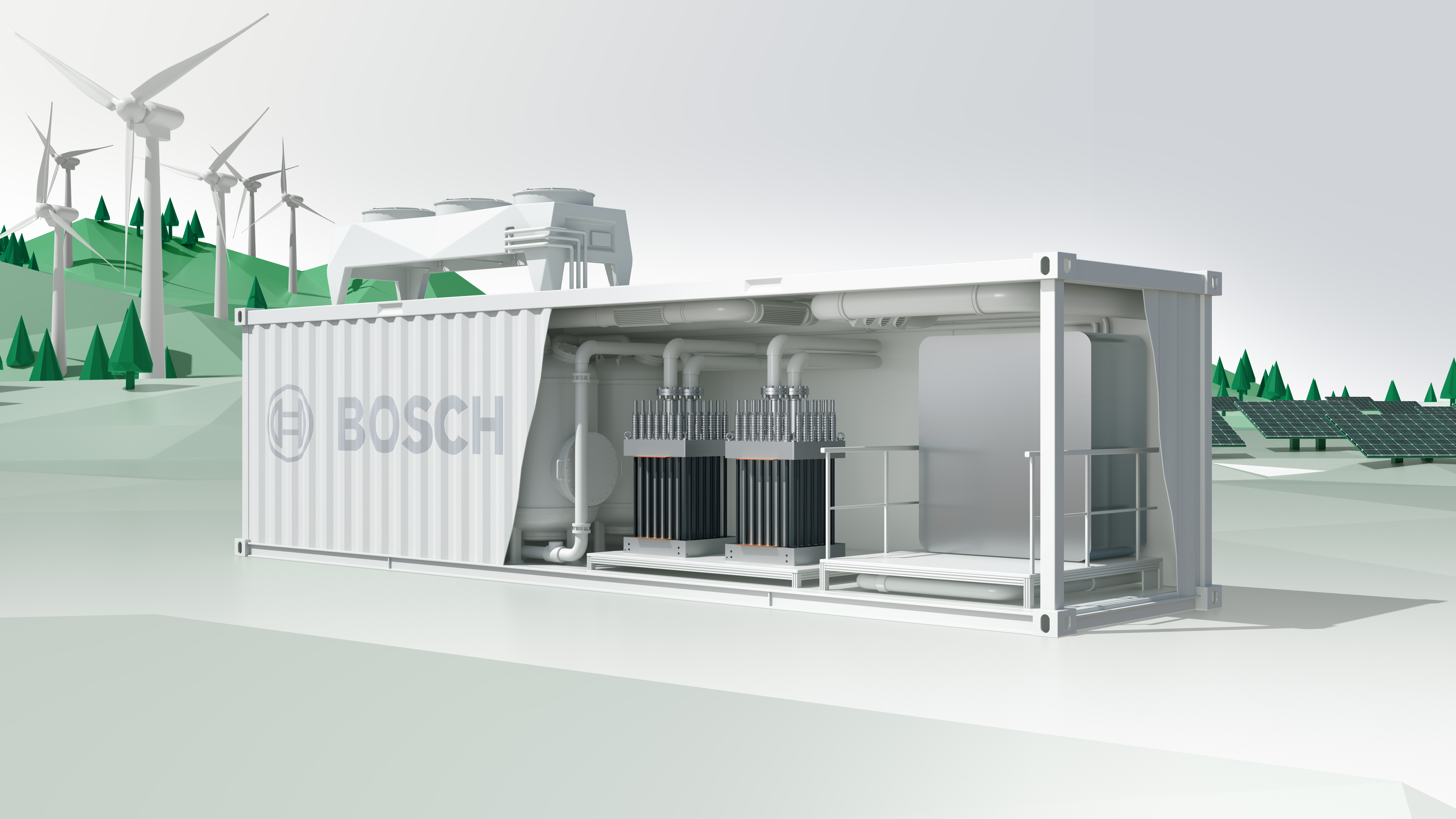

Bosch is also participating in the rapidly growing market for hydrogen production by developing components for electrolyzers. The company is developing the electrolysis stack – the core component of an electrolyzer, based on proton exchange membrane (PEM) technology. This stack comprises more than 100 electrolysis cells that use electricity to split water into oxygen and hydrogen. Currently the stack is on course for market entry next year.